There are millions of diamonds in the world today that have been cut to sub-standard levels. Re-cutting poorly cut or non-Excellent diamonds can be a profitable undertaking for jewelers. Many of the leading jewelers have been doing this with great success.

Evaluating the opportunity

The caveat is not to overestimate the potential yield and therefore overpaying. Having a 3D silhouette scanner on hand does make the task a lot easier as a diamond could be scanned and the re-cut weight estimated. Converting very good (VG) diamonds to Triple Excellent can often be done with minimal weight loss. Those are the easy ones.

When we get to severely compromised diamonds with girdles, tables or culets out of alignment, the weight loss could be significant. Diamonds with painted facets are less of a challenge than diamonds with dug out (scooped) facets. The latter takes more weight to rectify.

Establishing a course of action

Navigating the course of dealing with damaged diamonds can often be more daunting as the silhouette scanner and polished software would not suffice to get an accurate re-cut estimate. A good option is to have a scanner with rough diamond planning software (or to work with a diamond cutter that has one). Mitigating the weight loss and maximizing value when considering re-cutting often necessitates changing the shape of the diamond like converting a princess with broken points to a radiant, a pear with a broken point to a round or oval, or a marquise with a broken point to either a pear or an oval. These could be logical choices on the surface, however- some breaks on diamonds are complex due to the jagged or concave nature of some breaks and cavities.

The best way to evaluate a damaged (broken or chipped) diamond is to treat it like a rough diamond. The best option is to do concave laser mapping. The diamond is coated with an opaque liquid, which could be made from diluted correction fluid (white-out) to prevent the laser beam from entering the diamond as our goal is to scan the surface of the diamond. The laser scanner would measure the diamond in the concave mode and record all the detail of the whole diamond including the concave areas and cavities.

Scanning a diamond in three modes

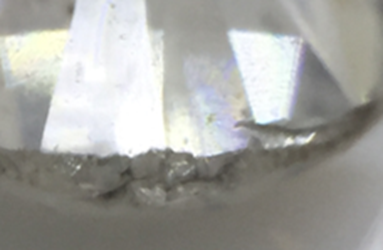

The image below shows a diamond with indented naturals in the girdle and a cavity in the pavilion/girdle. We have scanned this diamond in three modes. Firstly, as a normal polished scan, secondly as a rough scan, and thirdly as a concave scan.

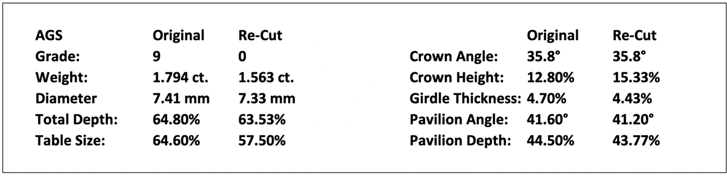

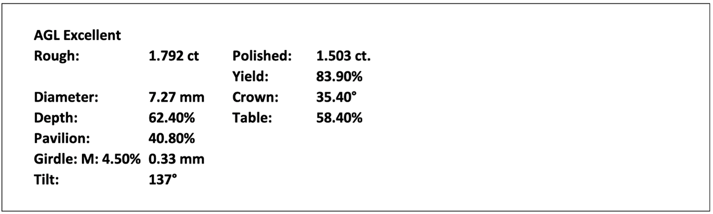

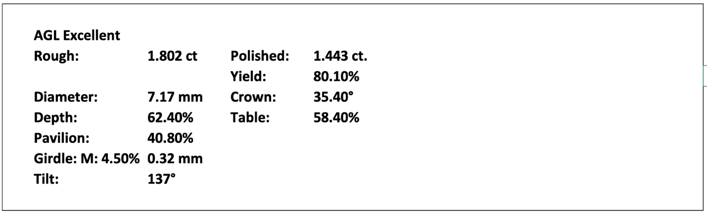

Following are the results of the three scans.

Figure 2 indicates a re-cut result of 1.56ct as an AGS 0

Figure 3 shows a re-cut result of 1.50ct as an Excellent cut.

Figure 4 shows a pre-cut result of 1.44ct as an Excellent cut.

Post scanning is decision time. Depending on the color and clarity, it might be better to decide on retaining the weight threshold of 1.50ct and settle for a Very Good cut grade rather than Triple Excellent or AGS 0.

Sometimes a crown break may require that the table of a diamond be tilted to remove the cavity as could be seen in Figure 5. This has some undesirable collateral consequences as the following happens.

- The culet goes out of center

- The girdle goes out of alignment with the table

- The angles and indices of facets are compromised

These facets can easily be fixed during re-polishing.

Opportunities abound for jewelers to improve their bottom line by trading or buying compromised or damaged diamonds. In case they cannot do re-cutting in-house, they can locate a reputable cutter to do their diamond repair work. Word of mouth is the best way to connect with a reputable cutter. Networking with other jewelers is a good way to go about it.

RapNet Blog

RapNet Blog

![Diamonds 6[1][1]](/media/2120/diamonds-6-1-1.png)