Titanium has a 20x greater tolerance for impact, compared to a traditional white gold basket setting. Is titanium a better alternative?

As a veteran in the diamond and jewellery industry I have seen my fair share of diamonds that were damaged by impact and other abuses. Having recut many diamonds over the past forty years, I have witnessed the shock and distraught of many owners over their losses. A question I have heard countless times was, ‘How can this be avoided?’ Well, as we all know there is always a reason for diamonds chipping and breaking in settings. The two main culprits are very thin girdles and not having enough metal to protect the girdles.

With the trend to expose more of diamonds to reveal their beauty, diamonds have become more vulnerable with four prong baskets and tension settings. This is not the case with bezel settings as the girdles of the diamonds are covered by the metal. This does however detract from the visible diameter of the diamonds.

Some years ago a jeweler approached me to explore alternative setting options that would protect diamonds from breakage. I have had my fair share of designing and proto-typing diamond cutting equipment and exploring various metals for optimal metal pairing to give me enough of a background to apply some of that knowledge in the quest for new setting options. I concluded that titanium would be the most viable setting option. Titanium is tougher than steel, hypo allergenic and can be polished to beautiful luster but, it is also a tough metal to work with. Its crystalline structure also makes it incompatible with precious metals as it cannot be laser welded to the traditional metals. My thinking was and still is that by using titanium for the baskets and then mechanically join it to the precious metals the best of both worlds, that is durability and beauty, could be achieved.

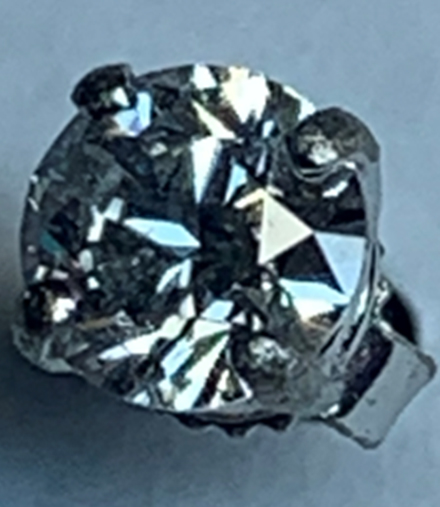

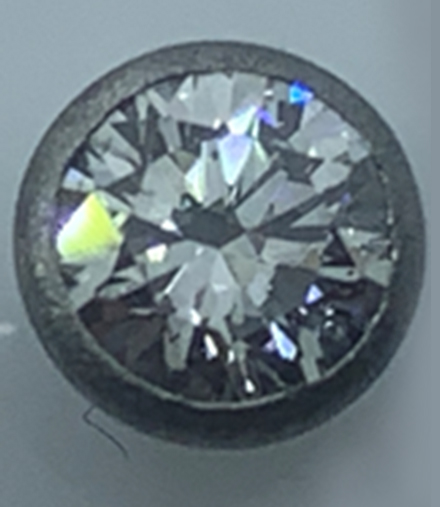

As our first attempt we made two ear studs using proprietary diamond cuts for evaluation. The baskets were machined out of solid bar. Here is a rendered image of the design.

Being such a tough metal, we could get away with very little metal peened over the girdle and crown.

The next step was to assess how well the ear studs would compare with traditional four prong studs by subjecting them to Impact Testing, Wear Analysis and Aggressive Wear Analysis.

Impact Testing

For our impact testing we used a tumbler with a drop distance of 1525mm (five feet), which is the average distance of the ear lobes to the floor for North American women. We opted for a worse - case scenario by fitting the tumbler with ceramic impact surfaces. We used two targets (ear studs A – 14ct white gold and B - titanium) as per the images below. Both targets were in an unpolished condition as they would be undergoing destructive testing anyway.

A |

B |

Alternating between the two targets, we subjected them to successive cycles of 100 impact events each.

After the first cycle of 100 impact events, both targets showed some surface damage. We subsequently repeated the 100 cycles for each target until we reached the 1000 mark. At this time, they looked as per the images below.

A-1000 |

B-1000 |

We then continued the intermittent cycles for each target until we reached the 3000 mark with the resulting damage as can be seen below.

A-3000 |

B-3000 |

We then continued the process for each of the targets with A failing after 3069 events as per the images below.

A-3069.1 |

A-3069.2 |

We continued with target B with 100 cycle increments and noticed that the metal progressively wrapped more over the crown with random micro peening caused by the impact events.

B-5000 |

B-10,000 |

B-20,000 |

B-20,000 |

B-30,000 |

B-40,000 |

B-50,000 |

B-60,000 |

B-63,744 |

At the 50,000 point the titanium started suffering some signs of fatigue which led to ultimate failure at 63,744 impact events.

In conclusion we found that titanium has a 20x greater tolerance for impact, compared to a traditional white gold basket setting, making a very strong case in favor of titanium.

Wear Analysis

We went ahead and re-set both diamonds in new settings to determine how the settings would compare in a wear test. We used a vibratory tumbler loaded with abrasive corundum/ceramic aggregate and water and subjected the targets to the wear test. They were loaded at opposite sides of the vibrating bowl and we were running them at 24 hour cycles. After each of the 24 hour cycles the targets would be removed, cleaned, inspected and weighed. Both targets tolerated the wear testing very well and showed little sign of compromise. What we did learn however is that the wear rate of the white gold basket was greater than that of the titanium basket.

Below are the images of the targets before the wear testing commenced.

A |

B |

The images below show the targets after 1008 hours.

A |

B |

Weight of targets including set diamonds at the beginning of testing cycle:

A – 0.296 grams

B – 0.2526 grams

Weight of targets after 1008 hours:

A – 0.2616 grams

B – 0.2492 grams

Weight loss for A was therefore 0.0286 grams and the loss for B was 0.0044grams.

In conclusion, the wear rates for the white gold basket is 6.5x greater than titanium.

Aggressive Wear Analysis

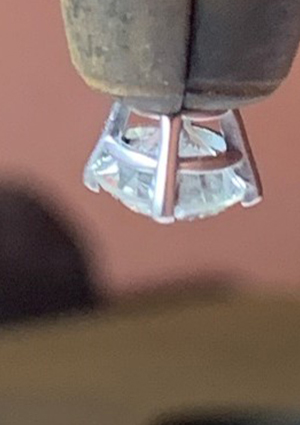

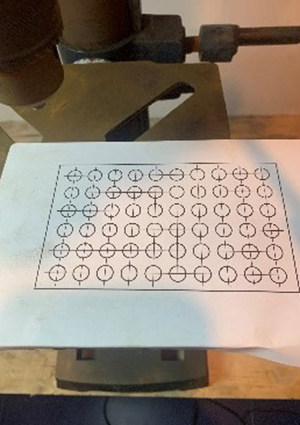

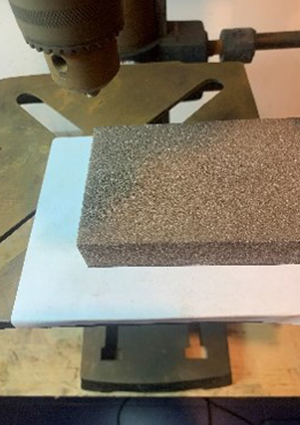

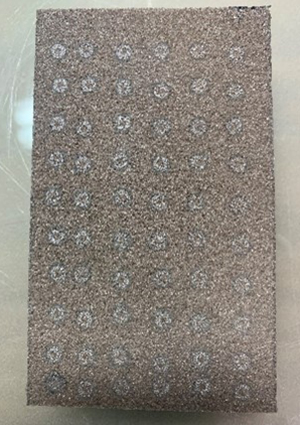

Our final step in comparing the two targets was to execute an aggressive wear analysis by using a drill press holding the targets and spinning them against a medium/fine sanding sponge pad for 10 second intervals and at a controlled distance of -1mm. The drill press was set for 900rpm. See images 1and 2. Images 3 and 4 show the grid pattern and sponge pad in position.

1 |

2 |

3 |

4 |

The same two targets used in the previous test was used for this final test.

Following the grid pattern, we ran the test until the point of failure was reached. At 37,500 rotations the white gold basket failed and the diamond was liberated. Notice how the abrasion profile changed on the pad as the wear transitioned from the metal to the diamond in image 5. Image 6 shows the liberated diamond. The titanium basket held up for much longer as can be seen by imprints on the pads in image 7 and 8 which were used on both sides.

Using both sides of the two pads allowed us to conduct 360,000 rotations. We then continued with a third pad and inspected the basket after another 18,000 rotations. The metal was worn away sufficiently for the diamond to be removed with ease at this stage. The reason it did not fall out was because it was a snug fit in the basket recess. Allowing for a margin of error of ±2%, we can safely assume that titanium withstood the aggressive test at a rate 10x better than white gold

5 |

6 |

7 |

8 |

Conclusion

The titanium basket turned out to be superior to the white gold basket by several magnitudes in all three tests, making a strong case in favor of titanium. Setting diamonds in titanium as tested will protect them from breakage or possibly falling out. Titanium can be polished to a very high luster and also anodized through a simple process into various attractive colors.

RapNet Blog

RapNet Blog

![Diamonds 6[1][1]](/media/2120/diamonds-6-1-1.png)